Beveling Machines

The double type beveling machine to process both ends of material continuously for high productivity

| Product Name |

KHW1000 |

KHW1360 |

|

|---|---|---|---|

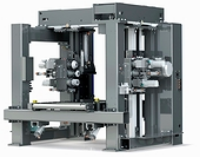

| Product Photo |  |

|

|

| Max. Capacity(W×H) | - | - | |

| - | - | ||

| 1000×500 mm | 1300×600 mm | ||

| - | - | ||

| Overall Dimentions(W×D×H) | 3130×4470×2560 mm | 3430×4470×2660 mm | |

| Machine Weight | 14400 kg | 15200 kg | |

KHW series is two beveling machines linked together as one unit; each machine works independently. The rear machine can cut the mirror image of the front machine; there is no need for flipping over workpiece which causes substantial machine down time.

DAITO H beam beveling machine KH series is developed as a quest of greater speed with reduced noise.

More and more end users select DAITO for high productivity and userfriendly operation.

Both data include 32mm of flange plane cut plus scallop cut.

The cutting noise is below 90dB; much lower than conventional models.

Plane/Scallop/Beveling cutters are all equipped with triplelinetips.

Together with optimized combination of cermet/carbide chips, the fine pitch tip cutters make quality cuts available.

Each cutter spindle quill moves back and forth to stay away from mechanical distortion for the smoother cuts and longer tool life.

Economical cermet chips are selected for speed spins of beveling/plane cuts; rigid carbide chips for scallop cuts.

■Plane Cutter

■Scallop Cutter

■Beveling Cutter

DAITO’s KH series is a fully covered machine to keep your employees safe from debris and your facility clean.

Gate Type Construction

Rigid construction along with triple-line-tip cutters enable fast and accurate beveling cuts with reduced noise and chatter.

Rigid Construction

In addition to highly rigid frame construction, the specially designed heavy cast iron vertical guide reduced cutting time/noise greatly to make full use of the cutters’ potential.

Automatic Scallop Shift

The scallop shaft positioning is made automatically according to programs without manual operation.

Tablet Type Screen

The operation panel is 10.4 inch Windows tablet. The programming is made by selecting preset work and cutting data. The data ex change via LAN or USB sticks is also available.

Direction Change By Inversion

The beveling direction change by cutters optional is easy together with automatic positioning function.

*Optional cutters are required for Inner beveling processing.

Flexible Products Flow

The product after cut is even available to return to infeed side or pass through the machine. This versatility is good at irregular jobs as well as spacesaving.

The reduced motor with a clutch drives every roller with chain to forward even a short workpiece.

The pusher at the infeed side pushes to align workpiece to feed smoothly to the machine.

The beveled chips are carried outside by the chip conveyor. A pit of 200mm depth is necessary to install.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

06-6489-1202(Head Sales Office)