| Product Name |

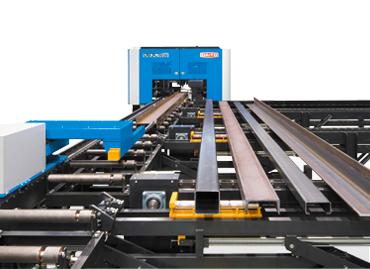

DB500 |

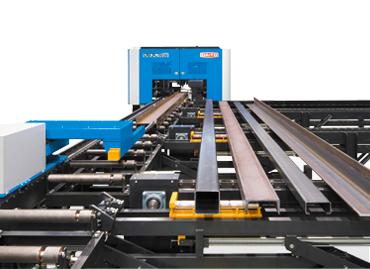

DBM500 | |

|---|---|---|---|

| Product Photo |  |

|

|

|

Max. Capacity(W×H) |

- | - | |

| - | - | ||

| 500×300 mm | 500×300 mm | ||

| - | - | ||

| Overall Dimentions(W×D×H) | 3249×2151×2814 mm | 3629×2151×2848 mm | |

| Machine Weight | 5500 kg | 6700 kg | |

DAITO’s Drill-Bandsaw DB500・DBM500 are automatic complex models of drilling machine and bandsaw. With tool changers of 3 axes, drilling, marking, milling (DBM500 Only) of various profiles are available on infeed side; bandsawing on outfeed side.

The model is a power-up version of DB500 with larger spindle motors to enable milling.

|

■DRILL UNIT |

|---|

|DRILLING

|TAPPING

|MILLING (DBM500 Only)

|LAYOUT MARKING

|CHAMFERING

| ■BAND SAWING |

|---|

|CUTTING

| ■AVAILABLE PROFILES |

|---|

DB500・DBM500 has an auto tool changers on each drill unit (top/left/right) together with a tool magazine of 8 tools.

By changing tools, different diameter holes, tapping, milling, long holes (DBM500 Only), marking (scratching & scribing), and chamfering are available on various profiles with optional tools.(Programming software DISⅡ is required for processing.) Finally the bandsaw cuts workpieces by programmed length.

DB500・DBM500 have variety of options as illustrated.

By combining options, the infeed/outfeed of various profiles are made automatically including discharging and sorting. With DISⅡ software, programs are converted from CAD data or previously input at office to increase productivity saving manpower.

■VERSATILE BANDSAW |

Unlike thick circular saws, the band saw is much more versatile to cut even small and thin workpiece since the thin saw blade is tensioned to cut. |

|---|

|

■SERVO-MOTOR-BALL-SCREW FEED METHOD |

The Servo-Motor-Ball-Screw feed method is not affected by temperature, unlike hydraulic method; always accurate and stable. The feed is free from any vibration, being backed up by a rigid saw frame on the linear guides. |

|---|

■SEMI DRY CUT |

Mist Lubricant is sprayed to blade edges. Unlike watered cutting fluid, both workpiece and the machine are kept clean to improve productivity. |

|---|

■OIL HOLE DRILL |

Being provided with cutting fluid directly to the edges, the oil hole drill runs high speed without heat-up. The tool life is even longer. |

|---|

■VERSATILE GRIPPER |

The gripper to position workpiece can manually select either vertical or horizontal direction to cope with various profiles. |

|---|

|

■WORKPIECE LENGTH MEASUREMENT |

The carriage press workpiece against the work buffer to measure length. |

|---|

■WIDTH MEASUREMENT |

The guide roller measures the precise material width. |

|---|

■HEIGHT MEASUREMENT |

The yoke roller measures the precise material height. |

|---|

■FLANGE HEIGHT GAUGE  |

Even distorted material, hole position is compensated by the flange height gauge. |

|---|

Even distorted angle, hole position is compensated by the work feed roller of fixed side.

Including H beam bottom, point marking from 4 directions is available.

In cutting lip C channel, workpiece is clamped from inside to avoid deformation. Even thin material is cut smoothly.

Programs are input previously at office; transferred via network or USB stick.

From each machine to total automation, contact us freely.

9:00~17:00: phone available

06-6489-1202(Head Sales Office)